Views: 550 Author: Hu Publish Time: 2025-08-08 Origin: Site

An expert buyer’s guide from Jiande Shuangjian Tools (Hangzhou Pro Tools Import & Export Co., Ltd.)

When you’re working on phones, laptops, game consoles, or lab instruments, a magnetic screwdriver can mean the difference between a smooth repair and a lost M1.6 screw inside a chassis. As a manufacturer with decades of OEM/ODM experience, Jiande Shuangjian Tools (model prefixes: SJT-S for single drivers, SJT-SS for sets, SJT-M for multifunction, SJT-H for hand-tool kits) engineers magnetic screwdrivers specifically for fine electronics work—balancing holding force, tip accuracy, and ergonomics.

Below are five factory-verified configurations popular with electronics customers. Each can be private-labeled or customized for retail and service centers. (Note: electronics repairs are typically done on de-energized devices; if you require insulated tools for live work, see our VDE ranges instead.)

Best for: smartphone screws, small appliances, camera modules

Tip: PH00, CNC-ground to DIN profile for minimal cam-out on micro fasteners

Steel: S2 tool steel (target hardness HRC 58–62) for long wear life

Magnetization: induction-magnetized tip; optimized holding force for M1.4–M2.0 screws

Handle: slim, anti-roll acetate core with TPR micro-texture; free-spin cap for fingertip control

Why it’s a top pick: clean tip geometry and a cap that tracks with your fingertip make steady torque easy in tight boards.

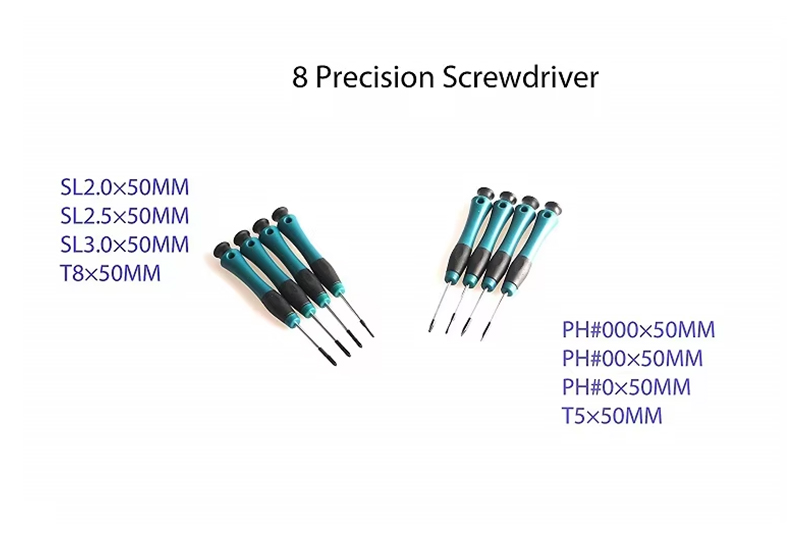

Best for: repair benches and field kits needing broad coverage

Bits (sample mix): PH000/PH00/PH0, SL1.5/2.0/2.5, Torx T2–T8, P2/P5 (pentalobe), Y000/Y0, Tri-wing 1/2, Hex 1.5/2/2.5

Holder: aluminum micro-handle with magnetic bit socket + swivel cap

Shaft: slim extension for deep wells; optional flexible extension

Storage: pocket box with size map; ESD-safe foam insert available

Why it’s a top pick: the magnetic socket keeps tiny bits and screws locked in while you maneuver around shields and cables.

Best for: repetitive teardown/assembly where speed matters

Mechanism: fine-tooth reversible ratchet for micro-torque applications

Bit interface: 4 mm micro-bits with rare-earth magnet in the head for strong retention

Grip: bi-material TPR with palm “dome” for low-effort ratcheting

Add-ons: short and long extensions; optional torque-limiting adapter for delicate threads

Why it’s a top pick: you keep tip contact while ratcheting, so fewer drops and faster cycle times.

Best for: static-sensitive assemblies, lab and service centers

ESD handle: surface-resistive polymer blend, dissipative to protect sensitive components

Tip: PH0 or SL2.0 with precision grind; black-oxide finish for grip (no glare under bench lights)

Magnetization: controlled-flux magnetization suitable for ESD benches (low-field option available)

Why it’s a top pick: combines ESD safety with the practicality of magnetic screw handling.

Best for: IT depots and classroom labs needing the essentials

Contents: PH000/PH00/PH0, SL1.5/2.0, T4/T5/T6, Hex 1.5/2.0 + magnetic bit driver

Driver: knurled aluminum barrel, strong magnetic socket, free-spin top

Case: slim clamshell; clear size legend; optional barcode for inventory systems

Why it’s a top pick: compact, durable, and covers the most common consumer-electronics fasteners.

| Model | Tip/Bits Focus | Magnet Type | Handle/Grip | Best Use Case | Notable Advantage |

|---|---|---|---|---|---|

| SJT-S Micro PH00 | PH00 single | Tip magnetized | Slim TPR + spin cap | Phone/camera micro-fasteners | Excellent tip access & control |

| SJT-SS24 Electro-Fix | 24-in-1 kit | Magnetic bit socket | Aluminum + spin cap | All-round electronics repair | Broadest bit coverage |

| SJT-M Ratcheting Micro | 4 mm micro-bits | Rare-earth in head | Bi-material TPR | Repetitive service work | Fast, low-effort cycling |

| SJT-S ESD-Safe PH0/SL2.0 | PH0 or SL2.0 | Low-flux tip | ESD-safe polymer | Static-sensitive boards | ESD + magnetic precision |

| SJT-SS10 BenchPro | 10-bit essentials | Magnetic bit socket | Knurled aluminum | Labs, IT depots | Durable, compact set |

One-hand starts in tight wells: Magnetic tips “park” the screw on the bit so you can align parts with your free hand.

Fewer lost screws: Prevents tiny fasteners from falling onto boards or into fan shrouds—reducing rework and time loss.

Higher placement accuracy: Stable screw positioning reduces tip wobble and cam-out on micro heads.

Speed gains on repetitive tasks: Especially with ratcheting handles, you maintain continuous contact while cycling.

Tip accuracy: CNC-ground profiles matched to DIN/ISO keep full engagement on PH000–PH0/T2–T6.

Steel & hardness: S2 at HRC ~58–62 resists rounding on micro fasteners; Cr-V options available for value lines.

Surface finish: Black oxide/phosphate improves bite and cuts reflection under microscope lighting.

Controlled magnet strength: Enough to retain M1.4–M2.5 screws without pulling nearby shims or labels; low-flux variants for sensitive sensors.

Ergonomics: Free-spin caps, anti-roll flats, and narrow necks enable fingertip torque and precise vertical alignment.

Branding: Laser or pad-print logos on handles and barrels; color-coded rings for size ID.

Bit maps: Region-specific assortments (e.g., include pentalobe for Apple service, tri-point for Nintendo).

Packaging: Pocket boxes, double-blister, or eco-kraft; multilingual cards and barcodes.

QC documentation: Batch hardness and holding-force checks available for enterprise procurement.

Model coding: Use your private-label SKUs or adopt SJT prefixes (SJT-S / SJT-SS / SJT-M / SJT-H) for internal tracking.

Work de-energized and use ESD controls when applicable.

Clean tips with isopropyl alcohol; avoid harsh solvents that attack handle polymers.

Protect tips in their case; repeated drops can affect magnet alignment and edge sharpness.

Replace worn bits promptly—rounded profiles slip and damage heads.

Match size to fastener: PH000 on M1.4, PH00/PH0 for larger; T2–T6 as specified by OEMs.

Precision manufacturing: CNC tip grinding and controlled magnetization for micro-screw handling.

Scalable OEM/ODM: From pilot MOQs to high-volume retail programs.

Electronics-ready designs: Spin caps, slim shafts, low-flux magnets, ESD options.

Global logistics: Retail-ready packaging, barcoding, and export documentation.

Sourcing & Samples: www.jdsjgj.com | hzjdsj@126.com | WhatsApp +86 137 3583 8908